Our Showroom

Experience our curated display of top-selling underwear styles — where brands explore fabrics, fits, and global market-ready designs.

Experience our curated display of top-selling underwear styles — where brands explore fabrics, fits, and global market-ready designs.

Quality Products Across All Categories

From Raw Material to Finished Underwear

From raw material inspection to final packaging, most production processes are completed within our facility. This integrated manufacturing workflow allows us to ensure stable quality, consistent sizing, and reliable delivery for global OEM and ODM customers.

All incoming raw materials are inspected before production. Fabric composition, weight, elasticity, color consistency, and surface quality are carefully checked to ensure they meet our manufacturing standards.

Fabrics are knitted according to product specifications. After knitting, each batch is inspected for structure uniformity, strength, and stability before moving to the next production stage.

Dyeing and printing are carried out under controlled conditions to achieve stable colors and clear patterns. Color fastness, shrinkage rate, and overall appearance are tested to meet different market requirements.

Fabrics are precisely cut based on approved patterns and size charts. Accurate cutting ensures consistent sizing and proper fit across different styles and production batches.

Cut pieces are sewn and assembled by experienced workers using industrial sewing machines. This step forms the main structure of the underwear, including seams, waistbands, and leg openings.

Finished garments undergo heat setting to stabilize size, improve shape retention, and enhance wearing comfort. This process helps maintain fit after washing and long-term use.

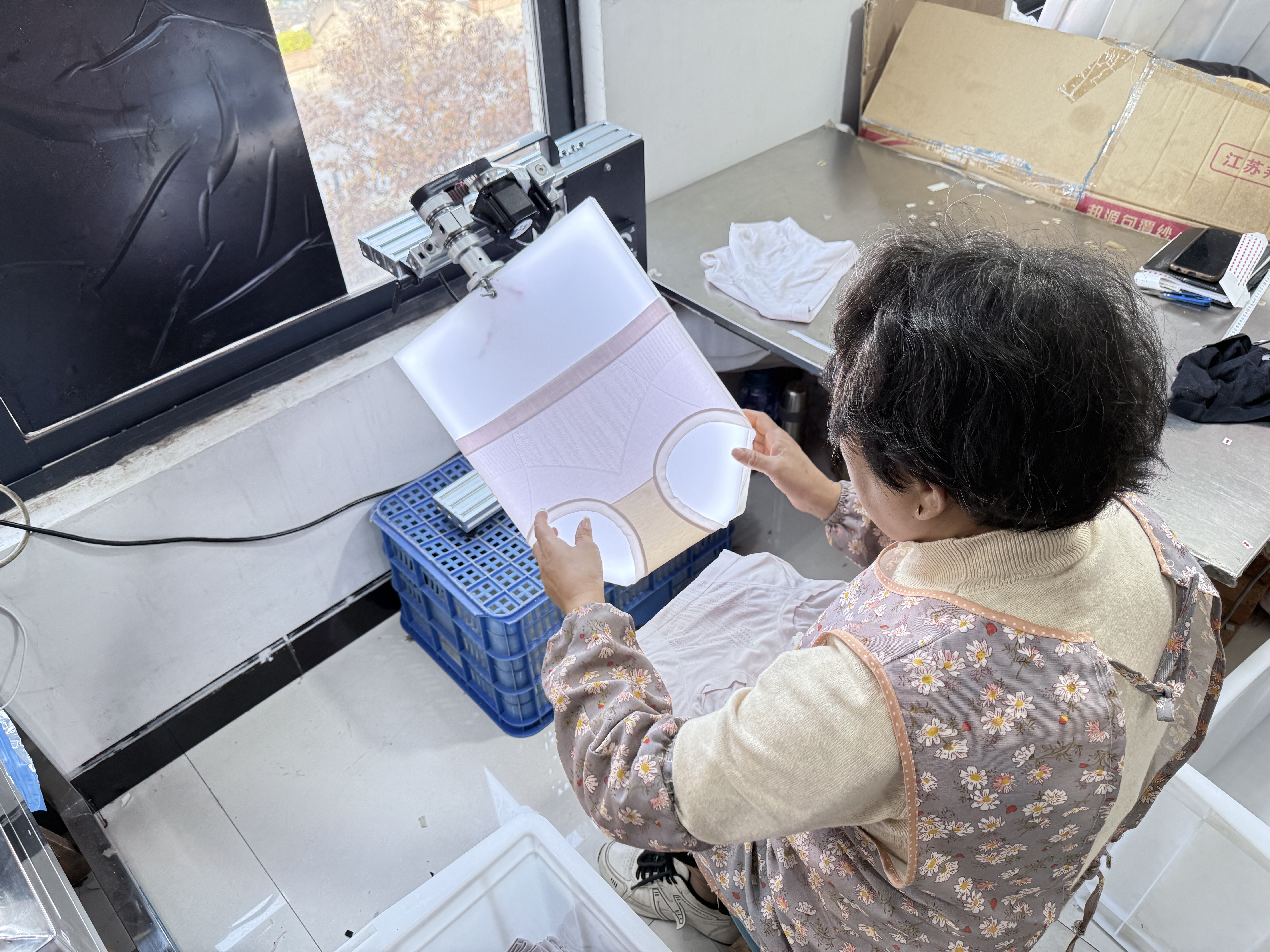

Each finished product is carefully inspected for stitching quality, measurements, appearance, and overall workmanship. Only qualified products proceed to packaging.

Approved products are packed according to customer requirements, including individual packaging, multi-piece sets, or bulk export packaging, ready for shipment.

Flexible packaging solutions to match your brand positioning and market requirements.

We support a wide range of packaging formats based on your sales channels.

Packaging and labeling customized to your brand identity.

Packaging prepared according to destination market requirements.

Packing solutions aligned with order size and logistics plans.

Get your personalized quote in 24 hours with flexible MOQ from 200 pieces